Formnext in Frankfurt

7-10 November 2023

HALL 12 BOOTH D62

Book your personal consultation with us at our booth.

The ALPHA LASER team opens up the world of 3D printing and shows solutions on topics such as laser welding, powder deposition and laser surface hardening.

OUR HIGHLIGHTS AT THE FORMNEXT

TALK TO AN EXPERT

Get a private consultation and all your questions answered

Additive Manufacturing through 3D metal printing is a multirole solution applied to many industries of the metal working sector. From dental to medical, from prototyping to R&D, from jewelry making to part replacement, the AL3D can print parts in almost any type of metal. Get a free consultation with one of our experts and see where we our printer fit to your needs.

SCHEDULE YOUR FREE APPOINTMENT

YOUR PROFILE IN 3D

Take part on our 3D keychain draw and win a steel miniature of yourself

Come personally to our booth at the Formnext to get your face and shoulders scanned to get a nice keychain generated by our AL3D-METAL and take part on our draw where we will choose 15 winners to have their profile printed on steel and added to a keychain.

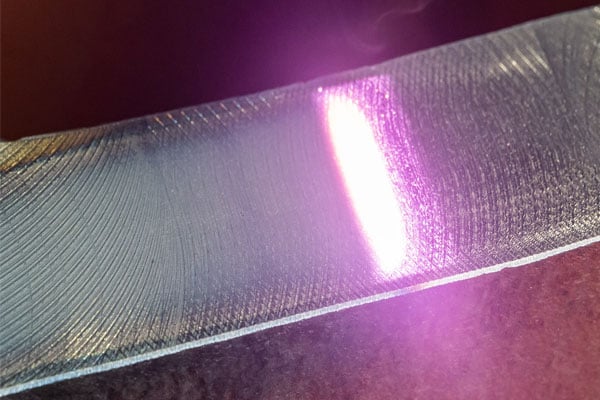

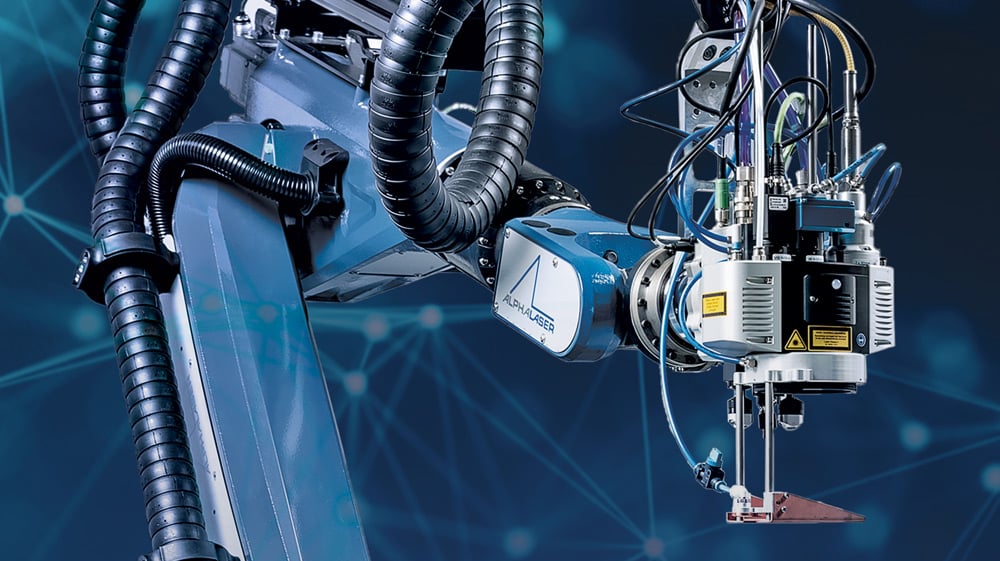

AL-ROCK mobile

Automatized surface hardening

The AL-ROCK mobile laser hardening system precisely scans and hardens components to prevent wear and tear without disassembly, saving time, reducing costs and decreasing your CO2 foot print. Aside from hardening our robot is capable of cladding, welding, and 3D printing.

The AL-Rock will be at our booth during the whole duration of the trade show. Come visit us at the hall 12, booth D62!

AL3D-METAL - THE POWER TRIO

YOUR WAY TO A SAFER AND EASIER POWDER MANAGEMENT

The ALPHA LASER's AL3D-METAL is an advanced metal 3D printer designed for precise and fast printing of complex metal objects. It offers high quality requirements, design and geometry freedom and uses powder bed based laser melting for >99.9 % material density. A closed powder circuit ensures safety by keeping the operator out of contact with the powder. Of particular note is the innovative cartridge system for quick powder changes, all-in-one software, and the ability to print precious metals such as gold, titanium, cobalt-chrome, platinum and more. With a compact footprint of

600 × 617 mm, it is also ideal for companies with limited space. This printer is particularly suitable for industries such as jewelry, dental, medical and prototyping.

In addition, our power trio, the printer, the cabin and the cartridge system ensure a lower down time with maximum quality.